- Siemens forms strategic cooperation in digitalization with Swire Coca-Cola, to jointly build 18 digital plants in future

- The Manufacturing Information System (MIS) customized for Swire Coca-Cola successfully launched in Hangzhou and to extended to about 100 production lines in the next two years

- To support Swire Coca-Cola build a group level data collection, analysis and presentation platform with software and hardware products and solutions covering big data, AI and MindSphere

- MIS to become the benchmark and standard for the manufacturing information systems of Swire Coca-Cola worldwide

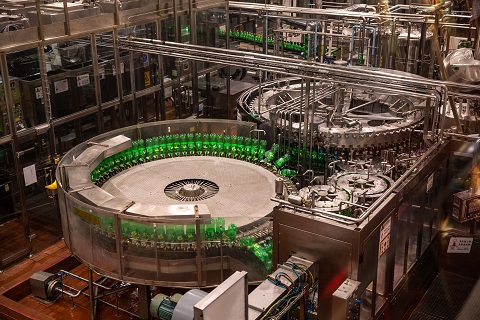

Siemens and Swire Coca-Cola China Co., Ltd today formed a strategic partnership on digitalization. The two sides will carry out in-depth cooperation in fields such as digital plant construction, supply chain intelligent management and training for digital talents, and to jointly build digital plant benchmarks in the beverage industry, aiming to promote digital transformation of Swire Coca-Cola in China and around the world. In addition, the Manufacturing Information System (MIS) customized by Siemens for Swire Coca-Cola has been successfully applied to its digital production line in Hangzhou, Zhejiang province. In the next two years, MIS will be applied to nearly 100 production lines in 18 plants of Swire Coca-Cola in China. Upon the implementation of the project, Swire Coca-Cola will unlock an annual production capacity of 550 million cans of Coca-Cola.

“The cooperation between Siemens and Swire Coca-Cola marks a step forward in the long-term friendship between the two sides. With the gradual implementation of the cooperation, I believe Swire Coca-Cola will make leaps and bounds in productivity, quality and sustainability, and set a new digital benchmark in the global beverage industry,” said Lothar Herrmann, President and CEO Siemens Greater China. “We hope to achieve tangible and fruitful results together. This is not just about production lines or plants. It’s more about creating new momentum in the manufacturing industry. Ultimately, it’s about innovating for the common good of people.”

Karen So, Managing Director of Swire Coca-Cola Co Ltd, said: “Currently Swire Coca-Cola’s application of digital tools has penetrated into different links including marketing, sales and supply chain etc. All our business people are equipped with mobile devices to timely check inventory, place orders, monitor execution status and take pictures, which helps us realize a comprehensive and closed-loop management of front-line business, execution and tracking, as well as production logistics. We can proudly say that in the so-called traditional beverage industry, we are at the forefront of digital transformation.”

In partnership with Swire Coca-Cola, the MIS was developed by Siemens based on advanced automation and digital technologies, software and hardware products and solutions as well as MindSphere. As another important practice between Siemens and Swire Coca-Cola in global cooperation, the system will become the benchmark and standard for the manufacturing information systems of Swire Coca-Cola worldwide in the future.

The system can realize the collection, processing, storage, utilization and management of data in all parts of the production process, and improve functions such as the information monitoring and analysis of the production process, quality control, equipment management and maintenance, warning and detection of faults, production performance evaluation and decision-makings. Benefiting from the transparent and visual management in the production process, the MIS can help achieve higher statistical efficiency, which greatly shortens the time for fault diagnosis and accumulates real data for further application of AI technology. This will help improve the digital level of the plant, and thereby enhance efficiency, realize predictive maintenance and save energy.

“Driven by demands of personalized consumtion, beverage companies are entering a new development stage that manufactering is driven by data,” said Wang Haibin, Executive Vice President of Siemens Ltd., China and General Manager of Digital Industries, Siemens Greater China. “The successful launch of the MIS marks an important milestone for both sides to jointly explore the digital transformation of the beverage industry on a large scale. Taking the cooperation as an opportunity, we hope to help Swire Coca-Cola further explore the infinite potential brought by cutting-edge technologies such as AI, big data and MindSphere, strengthen the supply chain of beverage industry and manufacturing flexibility, ehnancing the comany’s digital leadership and its brand value.”

In the future, Siemens will further expand the functions of the MIS system, including obtaining real-time production data nationwide through the APPs of Siemens MindSphere, analyzing all the data in multiple dimensions such as efficiency, energy consumption, safety, quality and predictive maintainence, so as to help Swire Coca-Cola achieve quality management at the group level and further improve the digitalization and intelligent level of its whole supply chain. At the same time, with the intereaction of the MIS and other systems in the production line, Swire Coca-Cola’s plants will save about 10 million kWh of electricity per year, equivalent to saving 3,200 tons of standard coal and reducing 7,500 tons of carbon dioxide emissions. It will be of great benefit to Swire Coca-Cola in fulfilling its commitment in energy conservation and emission reduction.

表示随着与西门子合作的逐步落地,未来太古可口可乐将成为全球饮料行业数字化新标杆.jpg)