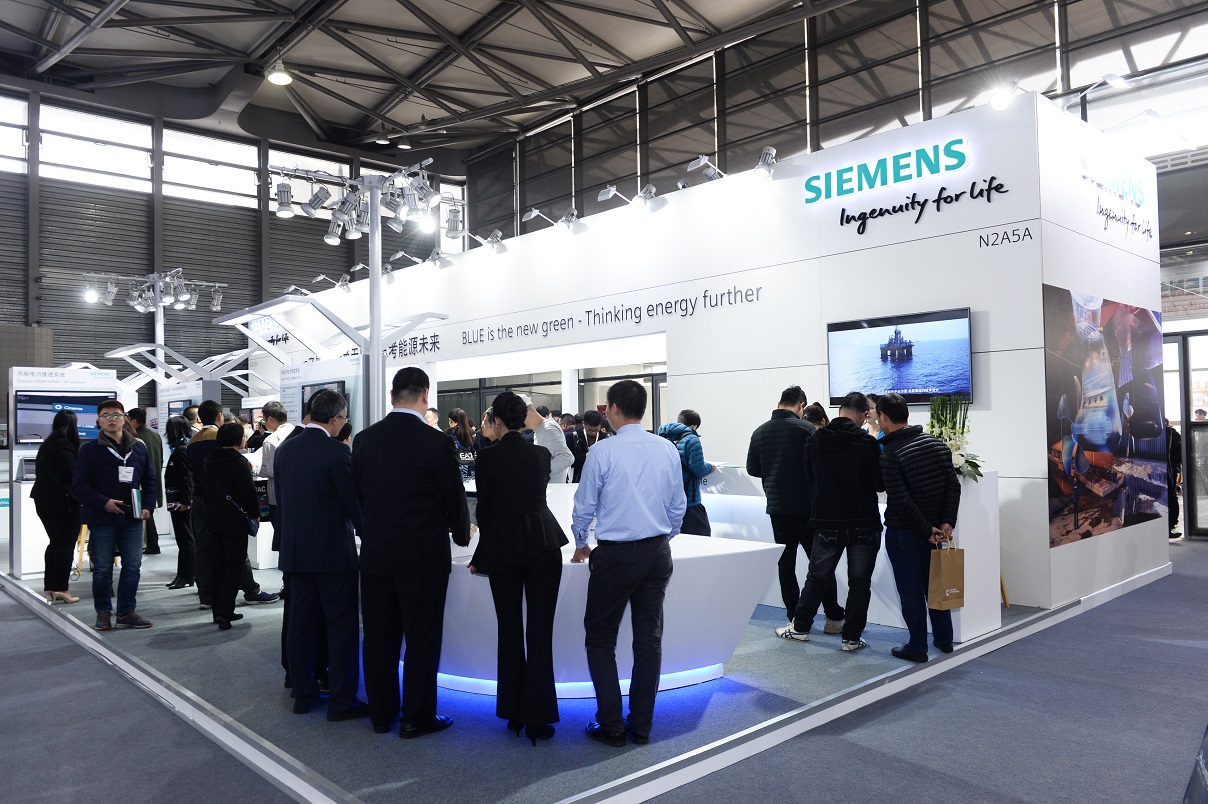

• Siemens participated the Marintec China 2019 with the theme “BLUE is the new green”

• Comprehensively showcased digital, green and energy-saving technologies and solutions for marine and offshore industries

• BlueVault energy storage and battery propulsion solutions meet the environmental and energy-saving requirements of the marine and offshore industries

Siemens comprehensively showcased its digital, green and energy-saving technologies and solutions for marine and offshore industries in Marintec China 2019 with the theme “BLUE is the new green”. Siemens exhibited leading diesel-electric propulsion system in the shipbuilding industry - BlueVault energy storage system, fully integrated solutions for all commercial vessels - SISHIP, especially the azimuthing podded propulsion system tailored for luxury cruise ships, digital solution TopSide4.0, advanced closed-loop power solution DP3 and eSiLoop solutions for offshore production platforms, as well as Cast-resin (Dry-type) Transformers widely used in the marine and offshore industries.

“‘BLUE is the new green’ is Siemens’ new interpretation of the future of marine and offshore industry, we are leading the industry towards a greener, cleaner and much environmental direction with innovative digital technologies. With our over 130-year experiences in marine and offshore industry, comprehensive industrial software and hardware portfolio, and the leading cloud-based open IoT operating system MindSphere, Siemens can provide all round support for the sustainable development and digital transformation of the industry,” said Qin Zheng, General Manager of Process Solutions, Gas and Power, Siemens Ltd., China.

EcoMAIN and Topside4.0 lead the digital future of marine and offshore industry

The integrated ship management system EcoMAIN, an element of SISHIP, is a multi-purpose integrated platform, which can access various data on ship operations through interfaces on ships and process and present the data in a consistent format. By evaluating and analyzing typical data such as fuel consumption, emissions, refueling, overhaul cycle, documentation and information management, EcoMAIN can optimize ship operations. Based on MindSphere, the ship platform communicates with shore-based server through satellites to realize the integrated lifecycle optimization management of the fleet.

Siemens also offers one-stop solutions for offshore production platforms, encompassing power generation and distribution systems, compression and production modules, automation instrumentation and communication systems, as well as lifecycle management system Topside4.0. Backed by MindSphere, Topside4.0 forms “Digital Twin” that combines the virtual world with the real world for offshore production platforms from design to production, commissioning, delivery and after-sales service, so as to provide support for management and decision-making of offshore production platforms across their lifecycle, shortening design and construction period and reducing operating costs. By far, the Topside4.0 concept has been applied to Ivar Aasen Field, an offshore platform of the European exploration and development company Aker BP, are helping it reach stable operation within one week and produce 30,000 barrels per day.

Extensive solutions meeting various green and energy-saving needs

Siemens has taken the lead in applying the DP3 closed-loop power solution on ships globally with CCS certification. The technology can effectively shorten the operation and maintenance time for main engines, improve their operating flexibility and fuel consuming, and reduce waste gas emissions. At present, the technology has been applied to more than a dozen ships. For example, it has helped the ultra-deepwater dual-rig semi-submersible drilling platform “Blue Whale I” successfully exploit combustible ice in the South China Sea. Meanwhile, Siemens DP eSiLOOP technology can save energy up to 11%, reduce carbon oxides and nitrogen oxides emission up to 35% and save a quarter of the construction costs.

As a leader in diesel-electric propulsion systems for the marine industry Siemens offers a complete range of marine propulsion system solutions, including medium/low-voltage and cost-effective electric propulsion systems. Amongst, the DC grid electric propulsion system BlueDrive PlusC is Siemens’ another significant innovation, which is a next-generation electric propulsion system based on variable speed generator and DC main busbar. BlueDrive PlusC can drastically reduce fuel consumption by 20% on average as well as greenhouse gas emissions. By integrating main switchboard with drive, it can save space and weight by 40%. The solution has already been used on “DA YANG HAO”, the China Ocean Association integrated resource survey vessel to be delivered in July 2019.

Siemens BlueVaultbattery energy storage System focuses on the marine and offshore application and has many references.The BlueVaults uses as the main power station for vessels, help shippowners comply with environmental legislation;save fuel through efficient engine used by enavling peaking shavings at times of high demand; increase safety with a back-up energy reserve that keeps systems running if failures occur,and reduce maintenance costs by lowering engine’s running hours. Siemens BlueVaulthas been installed in Color Hybrid, the world's largest hybrid-powered ferryin Norway, including 78 lithium battery cabinets with an installed capacity of 4.7 MWh, improving the propulsionflexibility, reducing operation cost and enhancing environmental performance.